COMMITTED TO THE RESPONSIBLE USE OF SPRAY FOAM CHEMISTRY FOR OVER 25 YEARS.

COMMITTED TO THE RESPONSIBLE USE OF SPRAY FOAM CHEMISTRY FOR OVER 25 YEARS.

Icynene spray foam insulation products have an excellent health and safety record spanning more than 425,000 projects over more than 25 years. Nonetheless, safe handling practices during and immediately following installation are required to eliminate the possibility of health effects from exposure to isocyanates. Asthma, other lung problems, and irritation of the nose and throat can result from inhalation of isocyanates. Direct contact with the skin and eyes can result in irritation. Different individuals will react differently to the same exposures; some will be more sensitive than others.

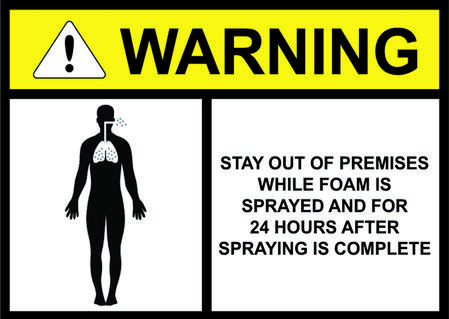

Everyone (other than Icynene-certified spray technicians) must vacate the job site, remaining completely out of the building or at least 50 feet away, while the spray is applied and for at least 24 hours after spraying is completed to allow active ventilation of the job site and to ensure the foam chemicals are completely cured. No exceptions.

For installations of low VOC products (Icynene Classic Max and Icynene ProSeal) in the United States ONLY, re-occupancy of the job site is permitted after 2 hours provided that the rate of air exchange during spraying and for 2 hours thereafter equals or exceeds 40 Air Changes per Hour (ACH).

Independent studies and third party toxicologist verification indicates that when the prescribed ventilation rates and periods are followed, Icynene spray foam insulation is safely cured.